bashan · We will carefully select products for you!

product center

-

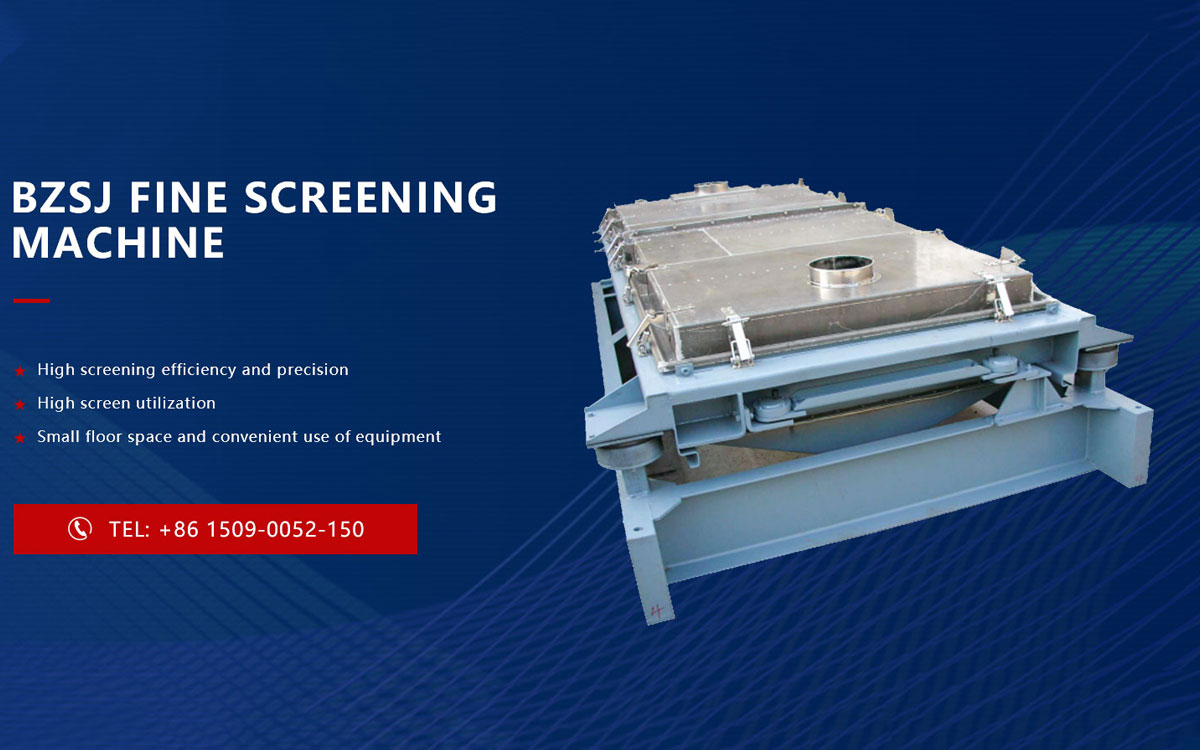

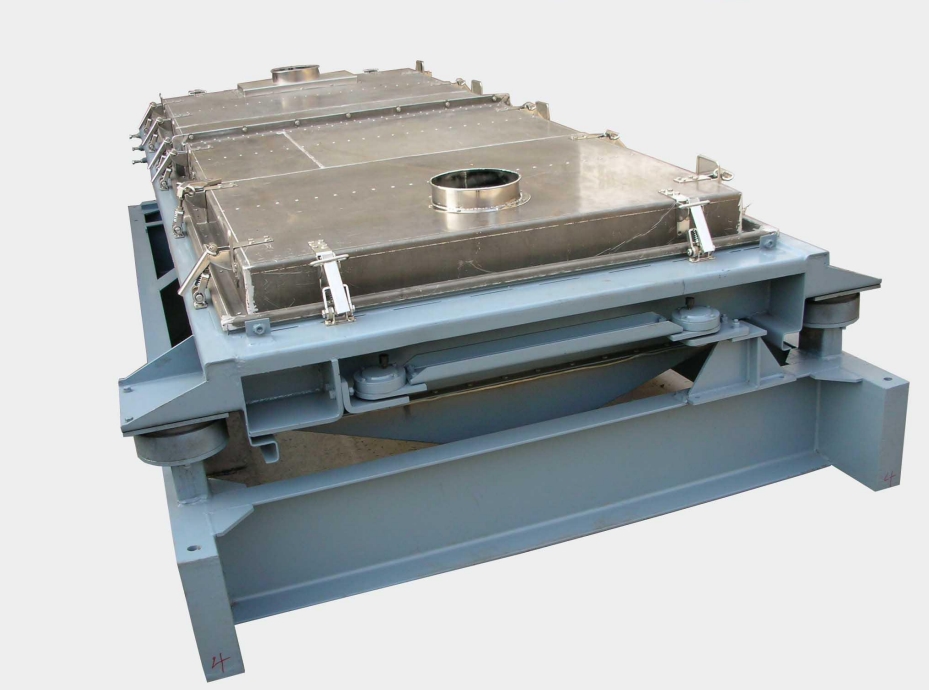

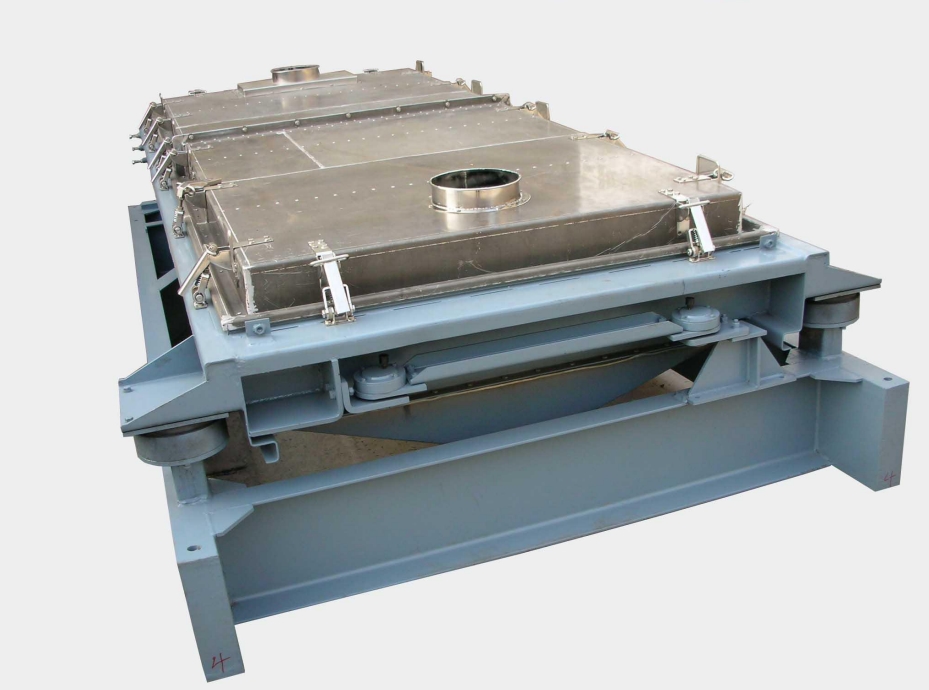

BZSJ Fine Screening Machine

BZSJ Fine Screening MachineGet Quote:+86 15090052150

BZSJ Fine Screening MachineGet Quote:+86 15090052150

High quality, low price, more to meet your needsMORE -

Linear Vibration Screen

Linear Vibration ScreenGet Quote:+86 15090052150

Linear Vibration ScreenGet Quote:+86 15090052150

High quality, low price, more to meet your needsMORE -

Specification

SpecificationGet Quote:+86 15090052150

SpecificationGet Quote:+86 15090052150

High quality, low price, more to meet your needsMORE -

Vibrating sieves--XZS Series

Vibrating sieves--XZS SeriesGet Quote:+86 15090052150

Vibrating sieves--XZS SeriesGet Quote:+86 15090052150

High quality, low price, more to meet your needsMORE -

Roller screen

Roller screenGet Quote:+86 15090052150

Roller screenGet Quote:+86 15090052150

High quality, low price, more to meet your needsMORE -

Lime milk screen

Lime milk screenGet Quote:+86 15090052150

Lime milk screenGet Quote:+86 15090052150

High quality, low price, more to meet your needsMORE