29

2022-12

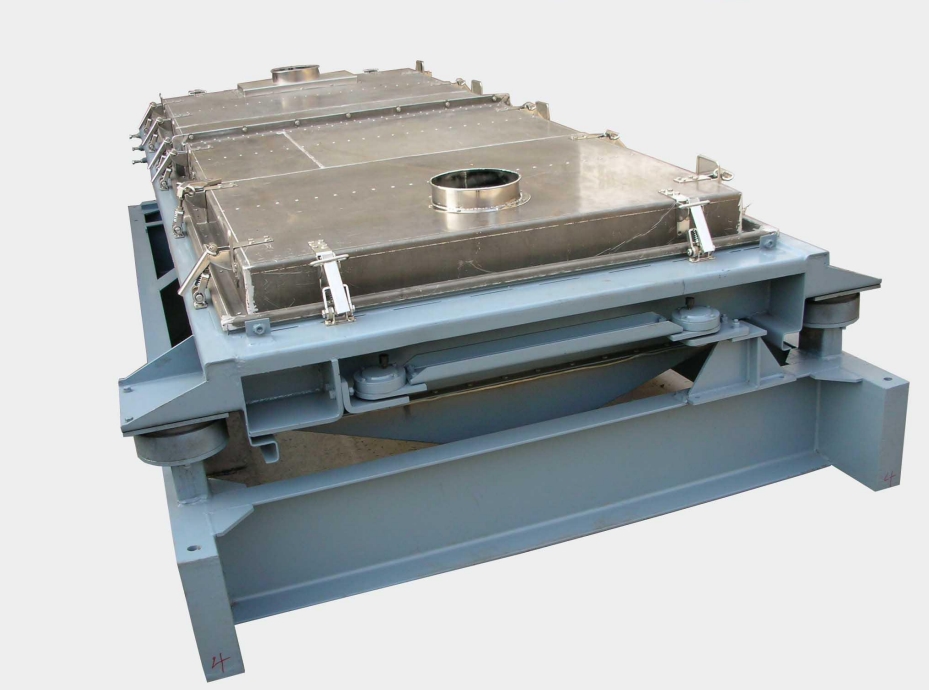

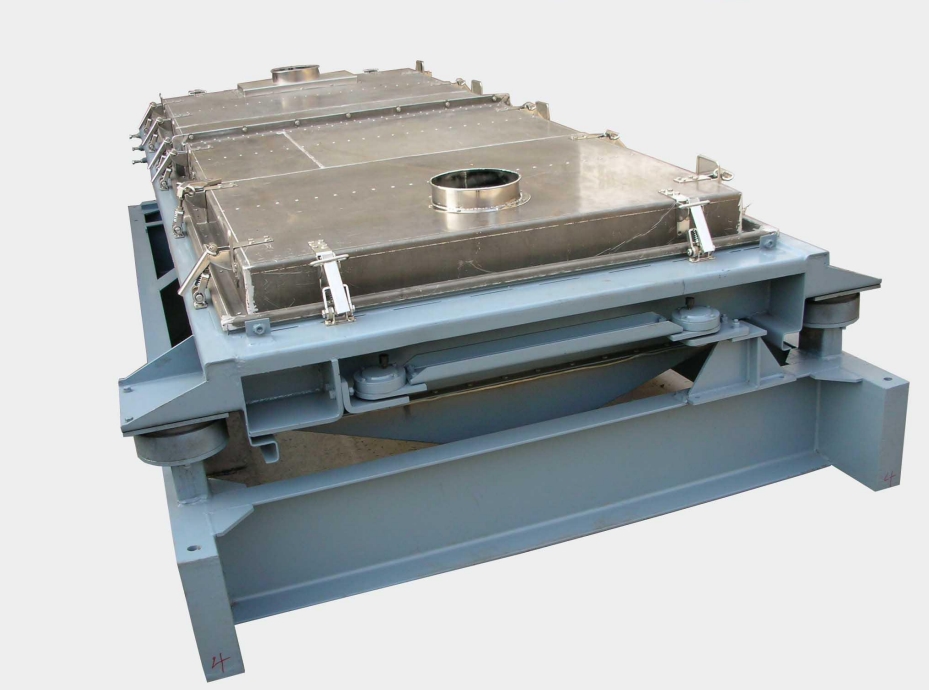

The manufacturer recommends you to use stainless steel vibrating screen when screening high-temperature materials

It is recommended that you use stainless steel vibrating screen for

screening high temperature materials. The whole machine is made of stainless

steel, which can screen high temperature materials above 200 ℃. In addition to

its high temperature resistance, it also has anti-corrosion, acid and alkali

resistance. The small editor of the stainless steel shale shaker manufacturer

will talk about the stainless steel shale shaker used for high-temperature

materials according to some questions frequently asked by screening users. High temperature materials are mainly used in the chemical industry, most

of which contain chemical substances, such as catalyst, cement clinker, ammonium

nitrate, titanium dioxide, vanadium, titanium slag, magnesium slag, furnace

slag, coal ash, etc. The stainless steel vibrating screen can not only meet the

high temperature screening of these materials, but also meet the screening of

powder, granular and small materials with the mesh size of 0.028mm~10mm of

stainless steel vibrating screen. The whole stainless steel vibrating screen has 304, 304L, 310, 310L, 316,

316L stainless steel. The higher the grade, the better the heat resistance and

heat insulation performance of stainless steel. It can withstand the screening

of high temperature materials at 200 ℃ - 500 ℃. In addition to good heat

resistance and heat insulation performance, the stainless steel vibrating screen

is less prone to rust after internal and external polishing and polishing, and

good cleaning performance can prevent high temperature materials from being

polluted. The stainless steel vibrating screen uses a vertical motor as the exciting

force, which can transform the rotating motion of the motor into a horizontal,

vertical and inclined three-dimensional motion, and then transfer this motion to

the screen surface. The screen surface makes high-temperature materials smaller

than the screen surface aperture fall to the lower layer through the screen hole

through the continuous vibration, becoming undersize materials. The

high-temperature materials larger than the screen surface aperture are

discharged from the discharge port after continuous jumping movement, So as to

complete the screening and grading of high-temperature materials.

MORE

29

2022-12

How to Solve the Hole Blocking Phenomenon of Drum Screen

Drum screen is a commonly used particle grading and screening equipment.

Because it is mostly used for sand grading, it can also be called drum screen.

The roller screen has simple process layout and is often used for grading and

screening of medium and fine materials to improve the quality of materials. As

the roller screen has many advantages, such as the screen hole is not easy to

block, the operation is stable, the noise is low, the screening cylinder can be

closed, it is easy to close the dust collection, the use of special screen mesh,

the screening efficiency is high, the service life is long and other advantages,

so it is widely used in daily industrial, mining and other production. But once

the drum screen is blocked, how can we solve it? Generally, the drum screen with larger screening particles will not be

blocked, and it will only be blocked when the screening particles are very fine

or the moisture is large. How can we solve the problem once the drum screen is

blocked? 1、 A device can be added to the fixed frame of the drum screen, and then

the device rotates to drive the belt installed on it to continuously tap the

surface of the screen hole, so as to extract the raw material particles blocked

in the screen hole. 2、 The impact block can be used for impact. This method requires enough

wall thickness of the supporting ring shaft sleeve to withstand the impact of

the impact block when removing the blocked raw material particles. 3、 The impurities blocking the screen shall be flushed by water flushing. A

stainless steel pipe with many small holes can be installed at the top of the

roller screen, and the impurities blocking the screen can be washed away by the

impact of water flow. With the development of society and the progress of science and technology,

Fangda Industry has also been developing new functions of the roller screen in

production. The screen mesh of the roller screen is a steel wire mesh, and the

size of the screen mesh can be configured according to the needs of users. The

discharge guard frame, roller frame and large underframe are connected by bolts,

which facilitates the transportation and installation of the machine.

MORE

29

2022-12

Specific operation and usage of standard inspection screen

The standard inspection sieve (also called inspection and analysis sieve,

test sieve) can be used in the pharmaceutical industry to determine the particle

size distribution, impurity content, solid content and other items of the

inspection department. The user can adjust the electronic delay device according to different

materials to reduce the error and judge the equipment quality. 1. Determine the screening tools to be selected according to the inspected

materials and corresponding standards; 2. Stack the sieve on the tray base according to the order of aperture from

large to small, from bottom to top, and position the sieve by groove or set

screw; 3. First, put the inspected materials into the upper screen, and then press

the screen with the screen head sheathed on the screw to tighten the nut on the

screw to press the screen; 4. Put the timer switch at the corresponding position, and then turn on the

power switch to run the screen machine; 5. After the standard inspection screen stops working, unscrew the nut on

the screw, remove the screen head, and carefully take away the screen; 6. After the operation, remember to cut off the power for safety. The standard inspection screen has the advantages of compact structure, low

noise, high efficiency, accurate accuracy, etc., and can generate multiple

high-frequency vibration.

MORE