Specification

Specification

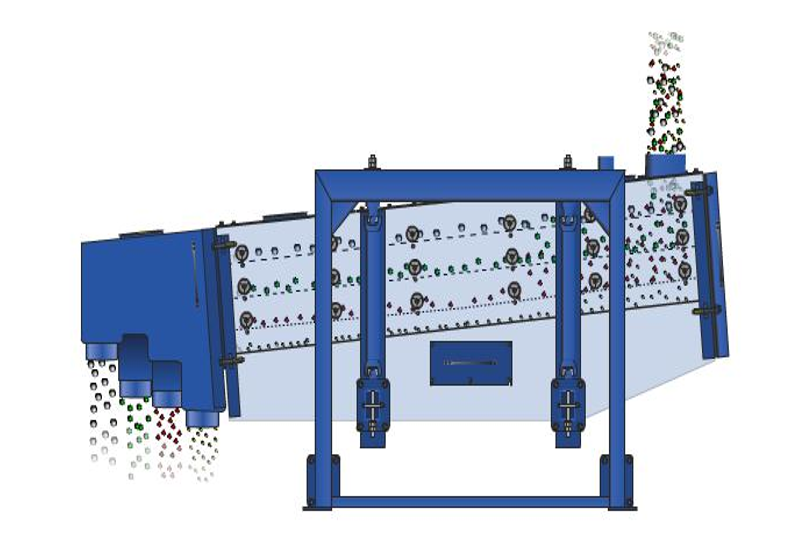

Equipment overview and photo:

The square rocking sieve is an efficient screening machine with high precision and large output. It’s equipped with self-cleaning mesh parts characterized by a long service life and good sealing effect. This machine is used widely in the sectors of chemical, new material, metallurgy, metal powder, mineral powder, food, salt, sugar, grinding material, and feed. In this equipment, a square rotary sieve transmits the rotation initiated by a vibration exciter to a screen surface, where the materials are dispersed quickly in the front part of the machine, thus achieving efficient screening.

Working principle of the equipment:

In view of the trajectory of the rocking body, i.e. the screen box, the rotary sieve is also called reciprocating sieve. The vibration force generated by the driving mechanism is an inertial load that changes in direction in a regular pattern around a fixed axis. It is essentially a reciprocating force of inertia resulting from rotation of the eccentric wheel around the fixed axis. Depending on structural characteristics and working principle of the rocking sieve, the screen surface is typically horizontal or slightly inclined (with an inclination of 0°~5°). The rotary sieve works on the following principle: After startup of the machine, the rocking body (the screen box) moves back and forth under the inertial force. The screen box drives the screen surface to rock cyclically, and consequently the materials on the surface rotate together with the latter. In this course, materials smaller than the mesh size of the screen surface fall to the lower layer as screen underflows, while those larger than the mesh size roll and tumble before being discharged from the outlet, thus completing the screening operation.

Product features:

With a fully enclosed structure, the screening machine generates no flying dust. It features low vibration and noise, and complies with environment protection standards. The materials move spirally on the screen surface and remain in contact with the screen surface for long. While maintaining original structure of the materials, the machine provides efficient, precise, and high-throughput sieving, making it an ideal choice for screening a diverse range of materials. The screen mesh installation system is capable of automatic tensioning and cleaning, thereby leading to a high utilization rate and a long service life of the mesh, and ensuring fast and convenient mesh replacement. Moreover, multiple layers of screen frame are made available to customers. Composite screening is also possible for doubling the production.

Main parameters of the equipment:

编号 No. | 名称 Name | 参数 Parameter | |

1. | 型号 Model | FYBS1030 | |

2. | 适用物料 Applicable materials | l 颗粒物质的颗粒大小从50微米到700微米不等 The particle size of granular materials varies from 50 micron to 700 micron l 筛物料的比重/密度为1.7 ~ 2.2 Kg/l The specific gravity/density of materials to be sieved is 1.7 ~ 2.2 Kg/liter | |

3. | 设备材质 Equipment material | l 与物料接触部分:SS316L不锈钢 Material-contacting part: SS316L stainless steel l 其他部分:碳钢 Other parts: carbon steel l 设备内衬为1mm 316L不锈钢板,外部为5mm碳钢钢板) 1mm 316L stainless steel plate as a liner, and 5mm carbon steel plate on outer surface | |

4. | 产量 Production | 1500~2000公斤/小时 1500~2000 kg/h | |

5. | 筛网 Screen mesh | 网架结构 Mesh frame structure | 框架勾边 With frame edges |

筛网面积 Screen mesh area | 4*3.0㎡(筛面规格:1000*3000mm) 4*3.0㎡ (screen surface size: 1000*3000mm) | ||

筛网层数 Number of screen mesh layers | 4层(5出口) 4 layers (5 output) | ||

筛网目数 Mesh number | l 35目、40目、50目、60 目、70目、80目、110 目、130目、160目筛网各一件。 One for each of the following size: 35-mesh, 40-mesh, 50-mesh, 60-mesh, 70-mesh, 80-mesh, 110-mesh, 130-mesh, 160-mesh. l 筛分物料的平均粒径要求为80 ~ 450微米 The average particle size of the materials to be sieved should be 80 ~ 450 mciron. | ||

筛网材质 Mesh material | SS316L SS316L | ||

6. | 电机 Motor | 品牌 Brand | 西门子防爆电机1MB0061-1CC2,防爆等级dIIBT4 Siemens explosion-proof motor 1MB0061-1CC2, explosion-proof degree: dIIBT4 |

功率 Power | 4KW 4KW | ||

电压 Voltage | 380V,50Hz. 3相电 380V, 50Hz. 3-phase | ||

7. | 筛面倾角 Screen surface inclination | 5° 5° | |

8. | 筛箱行程(mm) Screen box travel (mm) | 25~60 25~60 | |

9. | 冲孔板 Punch plate | 国产 Made in China | |

10. | 轴承 Bearing | SKF SKF | |

11. | 密封件 Seal | 硅胶,国产 Silicone, Made in China | |

12. | 传动带 Transmission belt | 国产 Made in China | |

13. | 润滑脂 Lubrication grease | 国产 Made in China | |

14. | 清网球 Mesh-cleaning ball | Φ35硅胶 国产 Φ35 silicone, Made in China | |

15. | 回转频次(r/min) Rotation speed ( r/min) | 180~264 180~264 | |

CASE

Related products

+86 15090052150

Scan for attention